Penetrant Testing

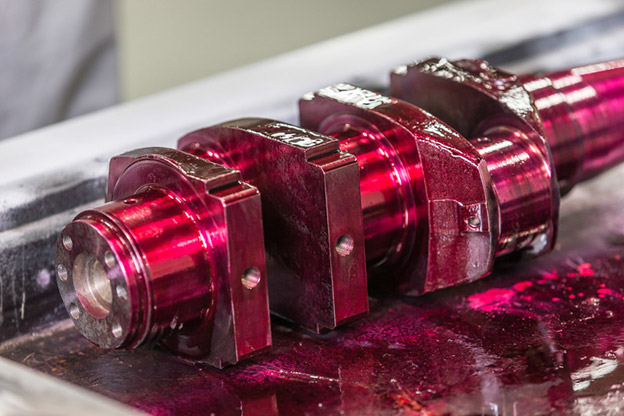

Liquid penetrant inspection (LPI) or penetrant testing (PT), is a widely applied and low-cost inspection method used to locate surface-breaking defects in ferrous, non ferrous and non-porous materials. LPI is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components.

LPI is based on capillary action, where low surface tension fluid penetrates into clean and dry surface-breaking discontinuities. Penetrant is typically applied in the field by spraying, or brushing. After adequate penetration time has been allowed, the excess penetrant is removed and a developer is applied. The developer helps to draw penetrant out of the flaw as well as provide contrast to enhance an indications visibility.

Metalogic provides multiple L.P.I. techniques dependent on your application and environment. To understand which technique is best suited for your project, please contact us info@metalogicinspection.com